Energy Monitor

- Home

- Metronomo.Net

- Energy Monitor

Monitor the energy consumption of your production assets

MECMATICA has developed a new software module integrated with Metronomo.Net's ERP-MES suite. It enables the monitoring of the electrical consumption of connected production assets: machine tools, compressors and other energy-intensive equipment in the company.

Energy Monitor's functionalities meet two types of needs. On the one hand, they control machine consumptions with a system integrated in Metronomo.Net's MES and detailed for each specific assets; on the other hand, they gather useful data to undertake a production certification process according to Green parameters.

Energy Monitor controls machine consumption through a plug-and-play system integrated into Metronomo.Net's MES. It also comes in a stand-alone version.

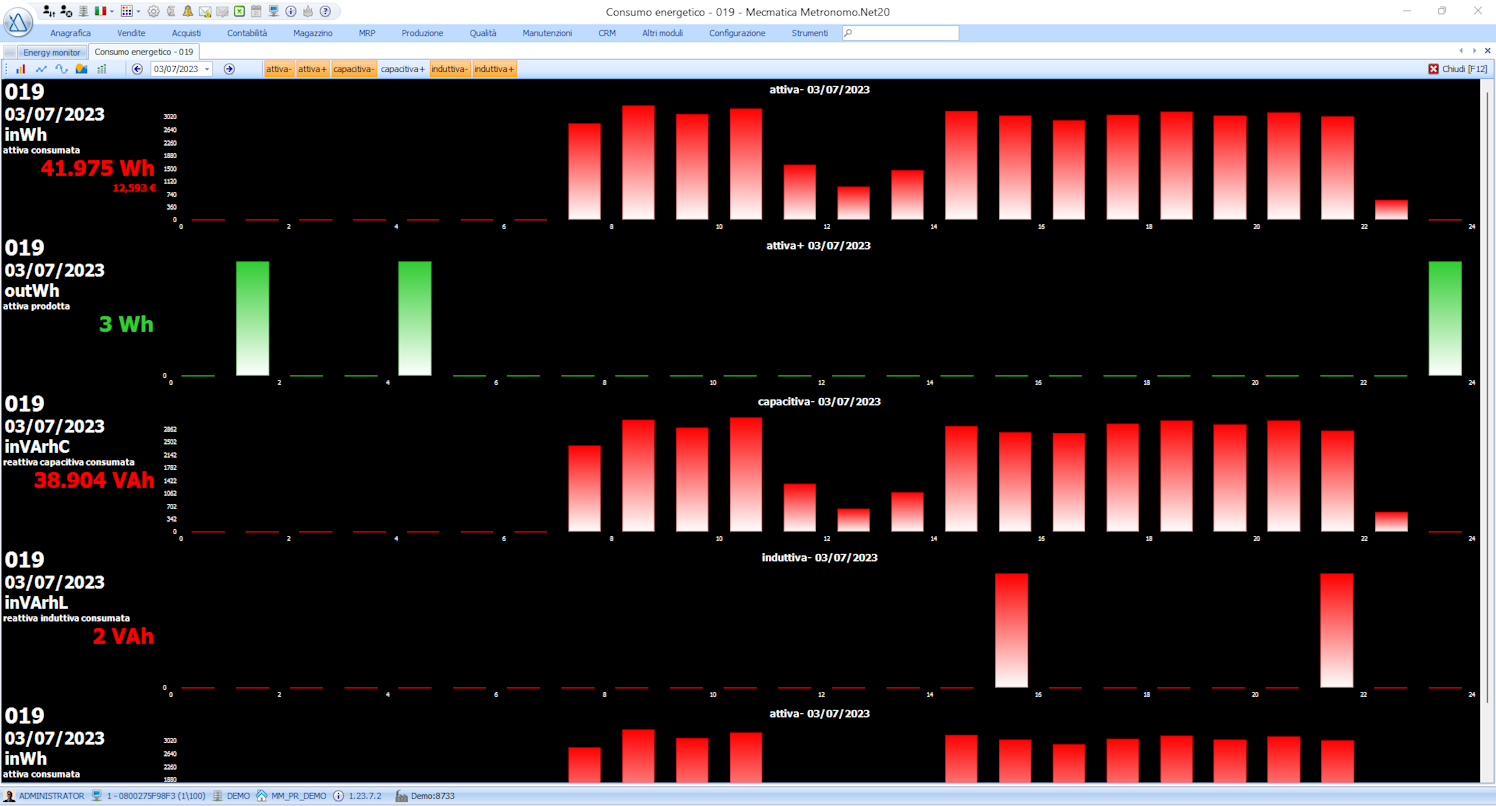

Dedicated hardware on the machine/asset displays the history of and monitors the electrical consumption of the connected asset in real time, based on specific parameters:

• total active energy consumed (inWh)

• total active energy returned (outWh)

• total inductive reactive energy returned (outVArhL)

• total inductive reactive energy consumed (inVArhL)

• total capacitive reactive energy returned (outVArhC)

• total capacitive reactive energy consumed (inVArhC)

With Eco Saving productivity equals sustainability

In NC machines with an Eco Saving function, the surplus of recovered power not used by the equipment is quantified and fed back as inductive reactive energy.

Storing data for a production certification process according to Green parameters

Energy Monitor archives and makes available all data necessary to be awarded with a sustainable production certification by a qualified external body.

Data analysis

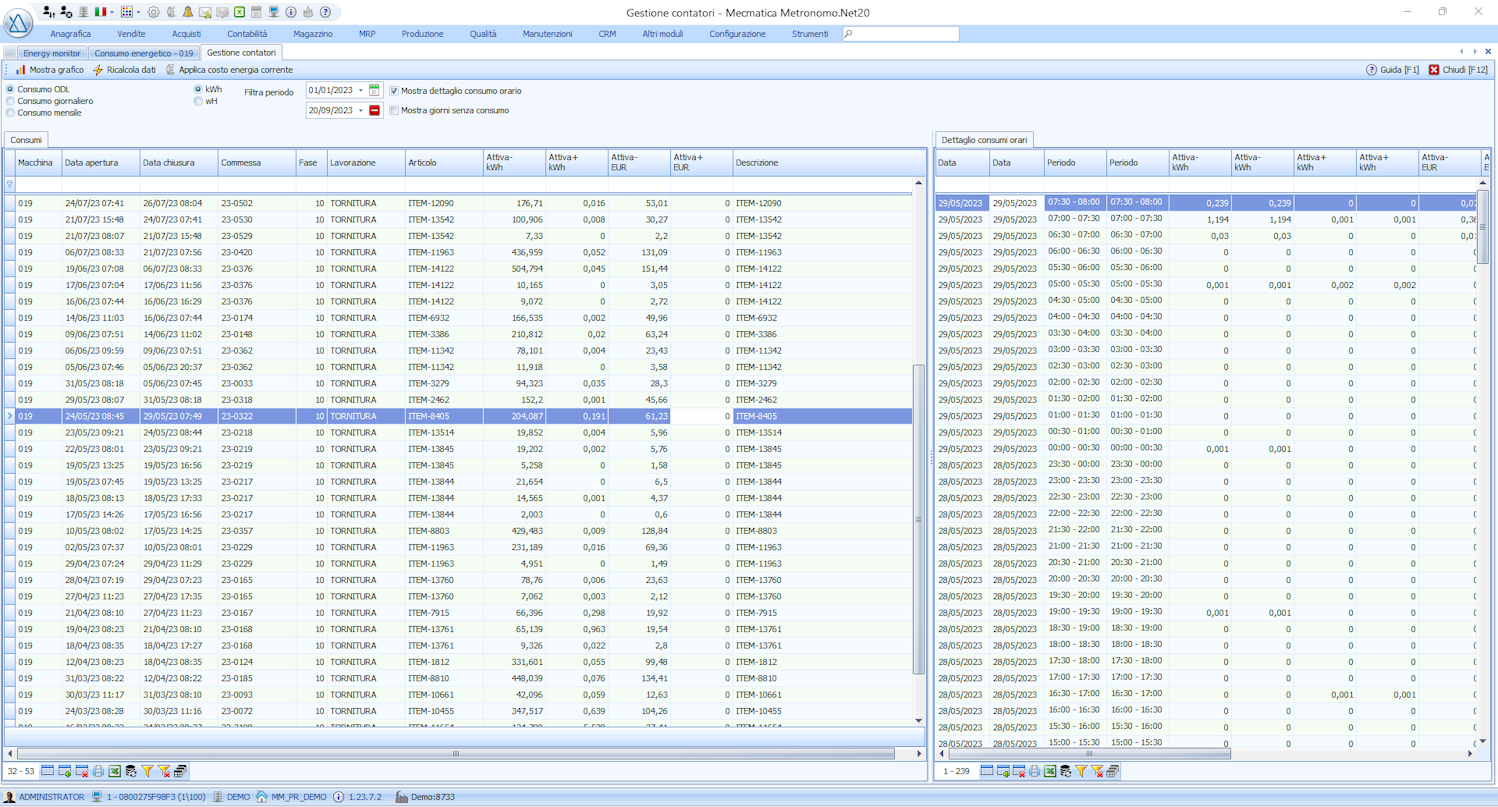

Consumption expressed in kW and VA is attributable to a specific work order being carried out on the machine, an order or a production batch.

The data collected and saved in real time are graphically updated every 30 seconds and immediately viewable by the user via a PC.

• Configuring Energy Alert Thresholds

• Performing production improvement analyses

• Configuring maintenance management

• Programmable via a dedicated Manumac module

• Calculating energy consumption based on specific features