Carpentry and precision metal working

http://www.industriebaraldo.it/Needs

Better management of production

Control the advances

Optimize the time

Implementation

With the advent of Industry 4.0, Industrie Baraldo was already ready and ahead of its time from the point of view of the digitalization of factory production processes. The first modules were installed at the beginning of 2015 and related to production management with its planning of various orders with the scheduler of Metronomo.Net.

In 2016, the real MES modules were implemented, installing touch screen info points for operators on board machine and starting to manage the technical budgeting within the system. Finally, in 2018, machine tools were interconnected to monitor production in real time. Today the software manages the whole production process of reality and is used by seven people in the office and by all the operators in the workshop.

Results

Precision in timing

Real-time monitoring of contracts

Organisation of data and availability of information

Increasing competitiveness in the market

Interview with Mauro Baraldo - General Manager

We ask Mauro Baraldo, young and competent General Manager of the Company, how has the work in subcontracting changed in recent years and what strategies they have adopted to remain competitive on the market:

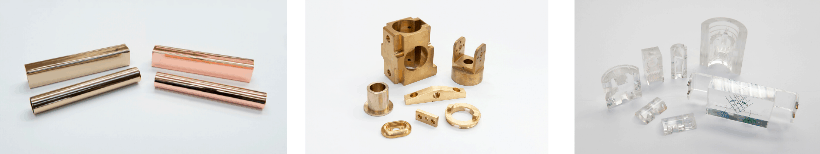

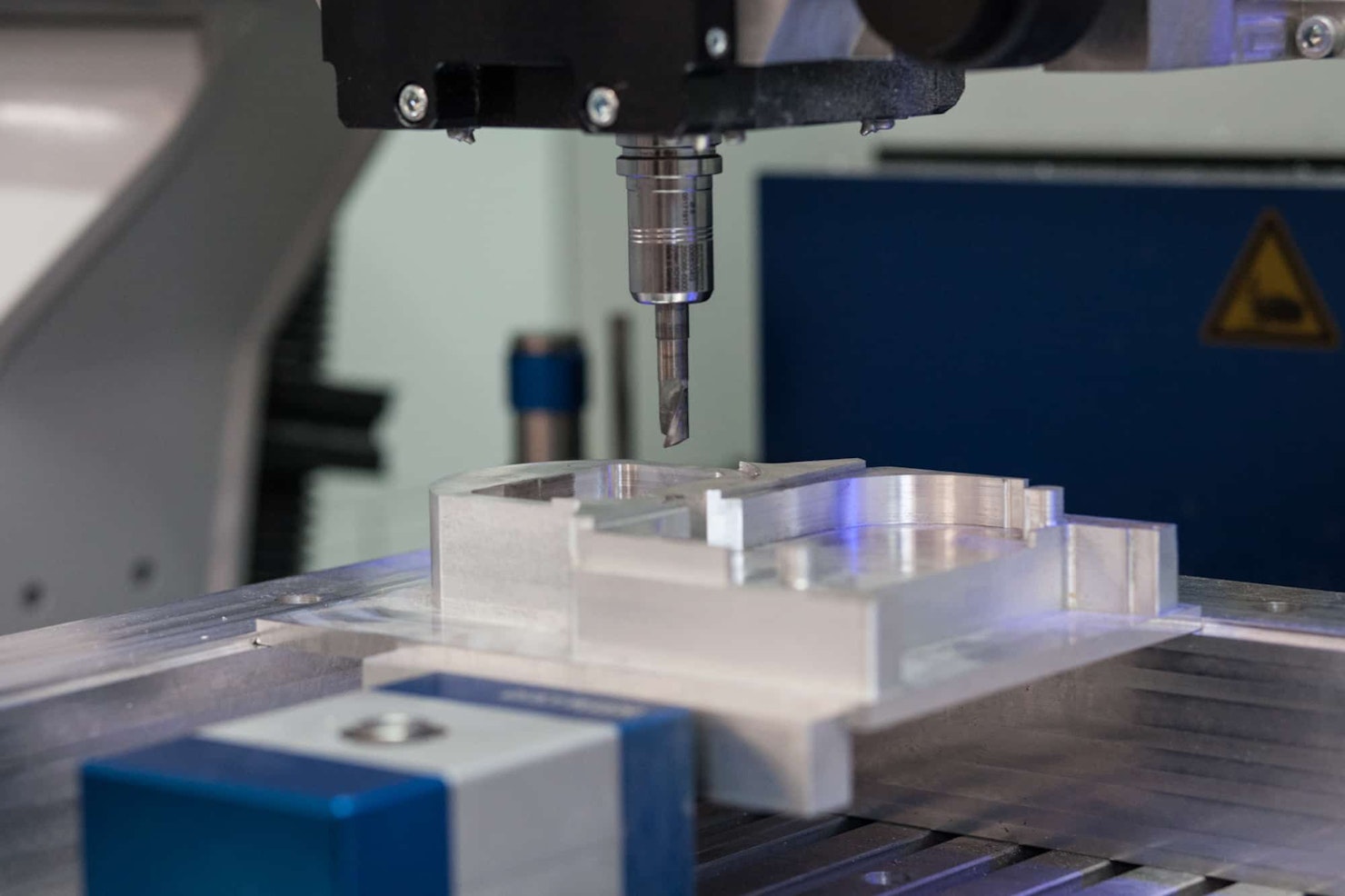

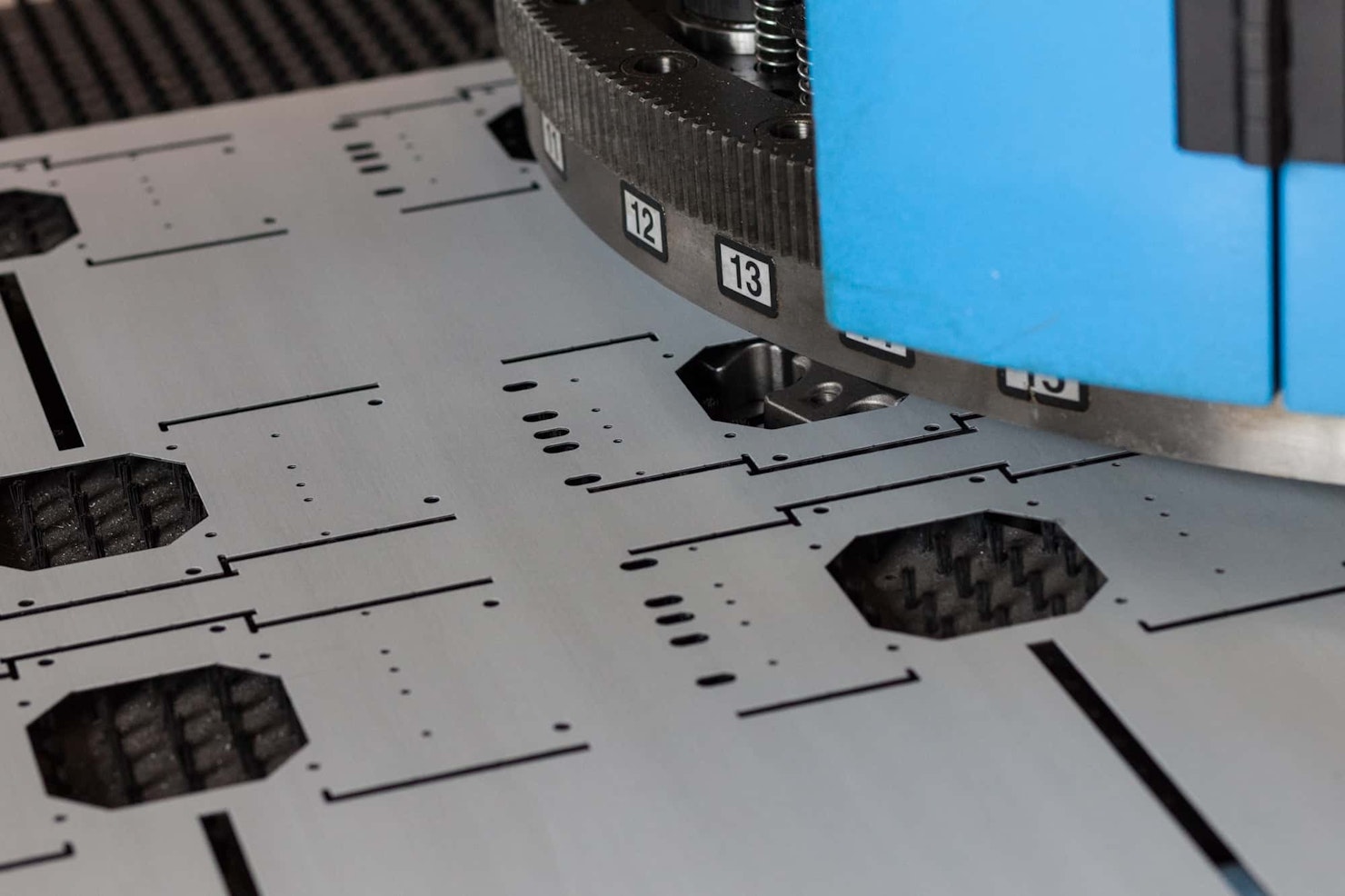

Industries Baraldo works with all the main metals and the most common plastic materials, offering its customers a complete design and prototyping service. We operate in a wide variety of technical sectors, ranging from medical to lighting and components for vending and packaging. Our vision is based on continuous improvement and our mission is to meet the demands of our customers.

What parts series do you produce today compared to the past?

One of the biggest changes for us has been to deal with the transition from the medium series of the past to small series, even to the single piece designed to measure. This step has been managed with "industrial method" thanks to the introduction of Metronomo.Net in the company. Also for the single piece in fact "we digitize every technical and commercial information" with the software modules provided by MecMatica Srl and this translates into a saving of time not only operational in workshop, but also in our technical office, which quickly retrieves the necessary information.

Have you approached new areas in sub-contracting?

In the last three years, production has also turned to the furniture/contract sector. This shift stems from a corporate desire to adapt to changing market conditions. The company has taken up this challenge by combining technical skills and punctual delivery times with very positive results.

What are your strengths?

Industrie Baraldo has had the ability to shorten the sub-supply chain by grouping together several fundamental steps within a single company, Thus reducing waiting times and making available to the customer expertise and specializations distributed on 4 production departments: design, sheet metal processing, CN machining of turning and milling, and welding.

So you consider yourself a 4.0 supplier?

With the advent of Industry 4.0, Industrie Baraldo was in fact already ready and ahead of its time from the point of view of the digitalization of factory production processes. I like to point out that today I couldn’t do without the Metronomo.Net scheduler. It allows us to give precise timing to customers, following in real time the progress of orders even for a few pieces. Of course we have NC machines connected in real time, but I think the real challenge for a quality subcontractor like us is the management of value-added business processes with information technology. This is a measurable competitive advantage for us and also benefits our customers.

How did you get to know MecMatica and what was the installation time?

We got to know MecMatica in 2014 thanks to an internal collaborator. The first modules installed at the beginning of 2015 were related to production management with its planning of various orders with the scheduler of Metronomo.Net. Subsequently, in 2016, we implemented the real MES modules, installing touch screen info points for operators on board machine and starting to manage the technical budgeting within the system. Finally, in 2018, we interlinked the machine tools, monitoring production in real time and making Industrie Baraldo a 4.0 company.

Today who uses the Metronomo.Net Software in Company and how was the training received?

Today the Metronomo.Net software manages the entire production process of our reality. It is used by 7 people in the office and by all operators in the workshop. We have immediately appreciated the competence and seriousness of the technical analyst who was entrusted to us, Mr. Nicola Rota, senior specialist at MecMatica Srl who has been with us since day one. Metronomo.Net is an intuitive software, easy to use and now we can plan all the different stages of production.

Metronomo.Net has been operating in the company for several years, what benefits have been brought?

Certainly we had some positive feedback regarding the organization of data and the availability of information. The paper data has been replaced by computer data available in real time and always reliable, we are very satisfied with the choice made at the time on Metronomo.Net. Our process digitalization journey started in 2015 has helped us, over the years, to be more and more competitive on the market.