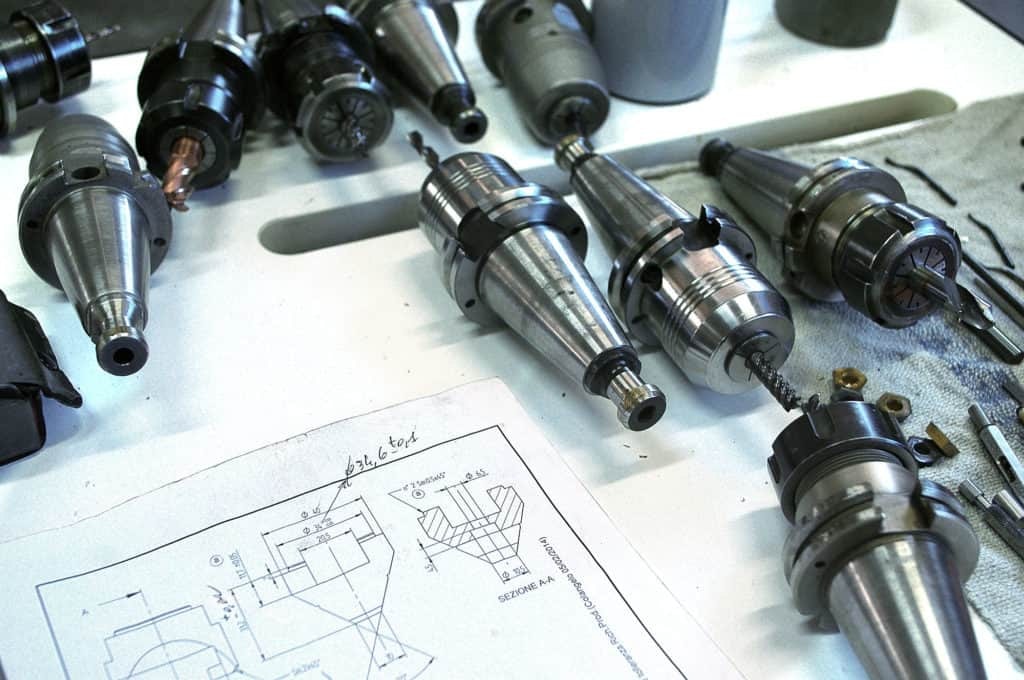

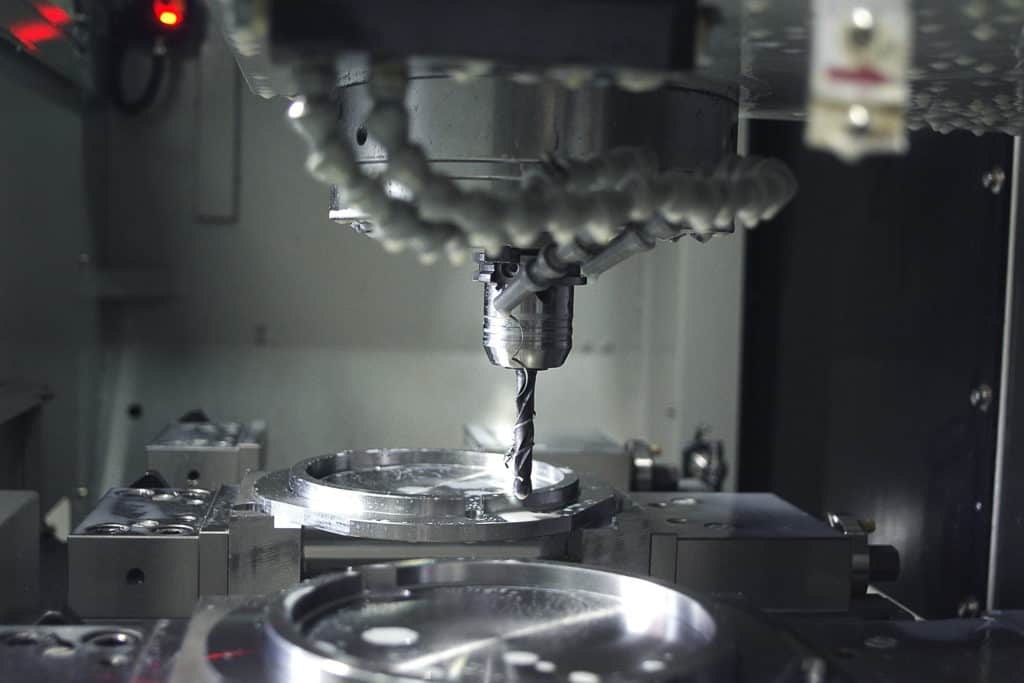

Precision machining

https://mancinsrl.it/it/Needs

The need for software that interacts with the whole production system

Connect both 4.0 machines and other traditional machines

Optimize the accounting area

Implementation

In 2015, the budgeting package was purchased, and later the modules of scheduling, accounting and inventory were integrated. The modules used to date are Quotation, Accounting, Inventory, Scheduling and MES complete with connection of machines and operator data collection.

Today it is used in production by all CN and Logistics operators; work is facilitated thanks to the two installed touch screen PC consoles; access has been enabled on all employees' computers. Being a system that monitors the entire production, it is useful for all staff to use it, to have a clear situation of the entire production department and a fast, reliable and updated information retrieval.

Results

Faster handling of DDT

Invoice conversion in XML format and direct interconnection with the Revenue Agency

Control of processes

Real-time monitoring of production

Access to accurate and up-to-date data in a few moments from all locations

Interview with Giulia Mancin - Owner

Why did you adopt a MES system like Metronomo.Net?

Previously we had already purchased the quotation package with MecMatica and after purchasing a 4.0 machine, we needed a software that made the whole production system interact. We have therefore opted to add the other modules of Metronomo.Net related to production to connect both 4.0 machines and other traditional machines.

How was the project implemented?

In 2015 we bought the budgeting package, then about a year ago we also integrated the modules scheduling, accounting and warehouse.

Which Metronome modules do you use?

The modules we use are Quotation, Accounting, Inventory, Scheduling and MES complete with connection of machines and operator data collection.

Do you also manage the billing part with Metronomo.Net?

Yes, using the Accounting part we realized that managing DDT was faster, so it made sense to link customers and suppliers' invoices as well. We moved the accounting part that we used to manage with our old management system, and for next year we plan to abandon it permanently and manage everything with Metronomo.Net. In addition, for the electronic invoicing speech, thanks to Metronomo.Net invoices are converted into XML format and interlinked directly with the Revenue Agency.

How many people use Metronomo.Net in your company?

Practically all of them! In production, all CN and Logistics operators use it thanks to the two installed touch screen PC consoles, and access has been enabled on all employees' PCs in the office. As a system that monitors production at 360°, it is useful for everyone to use and have a clear situation of the production and a fast, reliable and updated information retrieval.

Metronomo.Net has a user permissions authorization system and the licenses are floating for simultaneous access on the corporate server, an additional operational simplification.

What were the impressions about using Metronomo.Net?

It is not a complicated program because once you understand its operation it becomes very convenient. It has its logic, it is not difficult, it only requires commitment and constancy especially in the initial period regarding the loading of codes and data. I like the fact that they open under windows, that from each screen you can return to the previous order-item-order, that you can do so many chain steps that when you are looking for information are very convenient. We are waiting for new developments regarding the graphics of the program and the new Apps.

Now that Metronomo.Net is operational in the company, what has changed compared to before?

Previously we used Excel or paper files, so now it is much more convenient to search for information. We can in fact have a more real monitoring of production, you can find in a few moments updated and true data. In addition, all this data is accessible from multiple locations and by all the operators in the company, which was exactly what we were looking for. Before the hours of work of the machine were usually marked by employees, now there is a cycle monitored by a specific software. It is a reliable, accurate and fast system. We can say that the objective of actual production monitoring has been fully achieved.

How has the relationship been with MecMatica Srl and would you recommend it as a supplier of MES systems?

Yes absolutely. The reports were excellent from the beginning with the purchase of the quotation form. We are satisfied with the work that has been carried out over time, and we have been entrusted with a management analyst who is always available for training at our premises. We are also satisfied with the telephone and mail support, where there is always a response to our requests, nothing to complain about.

Twenty years of experience in MES systems and the same tool Metronomo.Net, have made it easy to manage innovation of Mancin Srl, we were among the first in the territory of Biella to believe in this path of business growth that we shared with supplier MecMatica.