Mechanical design and precision adjustments

https://mgmmeccanica.com/Needs

Align with the principles of Industry 4.0

Have a modern business impact

Keeping production under control

Safe handling of orders and respect of delivery times

Give the customer a complete and reliable service

Implementation

The collaboration started with the entry of the data, the creation of estimates, the management of production, scheduling and warehouse management. Accounting and Requirements Management (MRP) was added later.

Everything was done in a gradual way so as not to overburden the management and operators, avoiding the risk of slowing down production.

Results

Optimisation of the management of delivery dates thanks to schedulin

Reduction of errors in production steps

Correct and orderly management of warehouses and price lists

Control of movement history

Improved control of supply requests through MRP

Monitoring of production performance

Monitoring of production progress

Interview

What kind of company is MGM S.r.l. and in which sector do you operate?

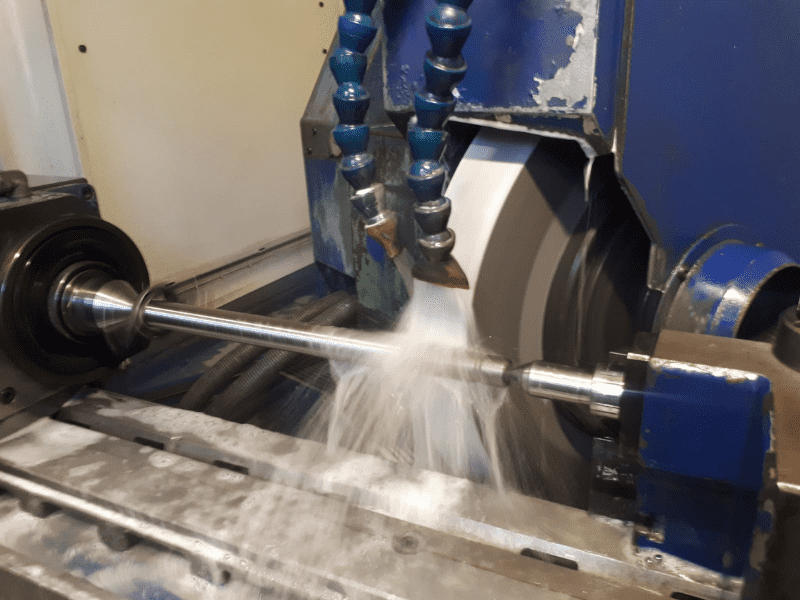

MGM is a production company that supplies various sectors ranging from automotive, machine tools, tool holder/ tool clamping, plastic molding, dental, power tools, oleodynamics, construction of parts for molds, Machining of sheet metal forming/cutting parts and parts for the production of electric motors. Over the years, it has also developed a wide specialization in round grinding and thread grinding.

What are your strengths?

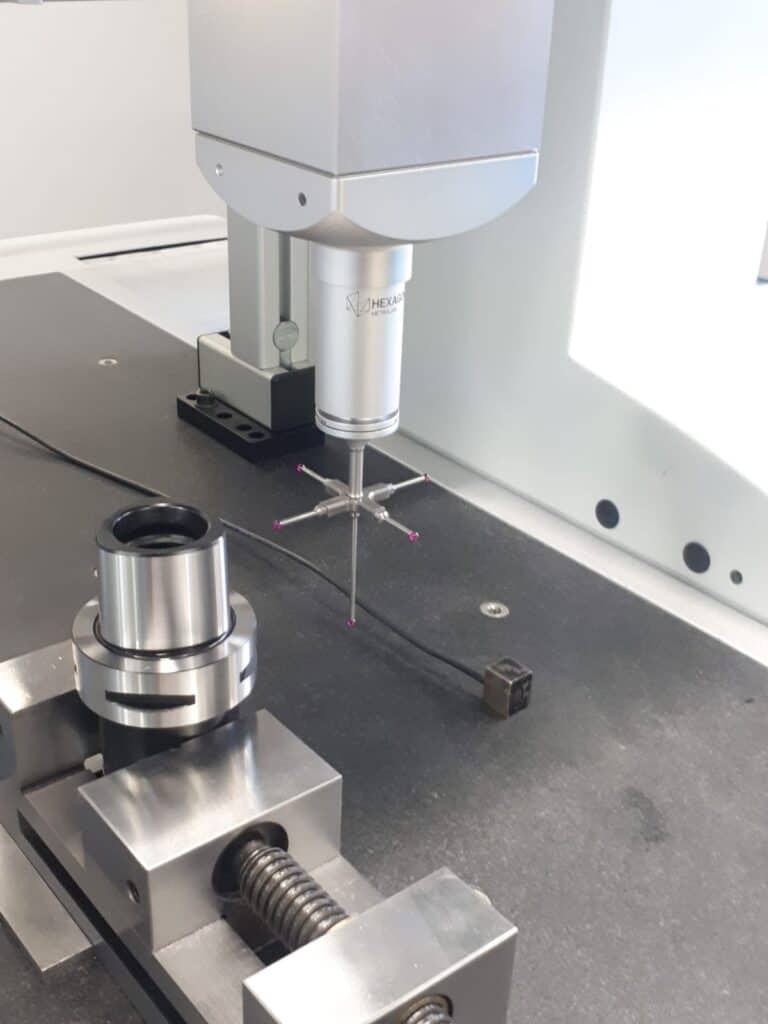

Our strengths are in general the precision adjustments even with very narrow tolerances, ranging between micro diameters and dimensions within the meter, and the rectification of shapes and threads with the possibility of being able to control the entire production process thanks to a state-of-the-art metrological room. In addition, as far as contract management is concerned, it ranges from a single piece to volumes of a few thousand.

What was the need to choose a new manager?

Regarding the introduction of a new management system in the company, the main motivation was given in particular by the need to enter into the ideology of Industry 4.0 so as to have a modern business impact and keep production under control, so that we can give the customer an additional security on the management of their orders and the security to meet the delivery deadlines.

We also needed to control the production times in detail so that we had under control the costs of realization in a precise and optimal way.

What kind of software selection did you make and why did you choose Metronomo.Net?

We have evaluated other software and from a wide selection we found ourselves to choose between two, Metronomo.Net and another. It was a rather difficult choice but in the end the simplicity and completeness of Metronomo.Net prevailed

How did the introduction and implementation of Metronomo.Net in the company go?

The introduction has taken place step by step. We started with the entry of the data, the creation of estimates, production management, scheduling and warehouse management. Accounting and Requirements Management (MRP) was added later.

Everything happened in a gradual way so as not to overload us and our operators too much not going to slow down the production.

I must also admit that thanks to the help of MecMatica’s technical and sales team, everything was easier.

Metronomo.Net has been operating in the company for several years, what benefits have been brought?

The advantages I must admit that they are numerous: from a better management of delivery dates thanks to scheduling, a reduction of all errors in the production phases so as to avoid forgetting about the opening/closing of the phase, a correct and orderly management of the warehouses with the possibility to keep under control all the history of the movement, a complete management of all the lists and, finally, thanks to the use of MRP you can manage the best supply requests.

In addition, the connection of all machines to Metronomo.Net keeps track of production progress giving an immediate status of production progress.

How have you and are you facing the current global situation caused by the pandemic?

During the pandemic, fortunately, several of our sectors have continued production, see the plastic molding of the pharmaceutical sector and electric motors, We have never stopped or even due to the closure of several businesses we received numerous requests from new customers.

Strategies and plans for the future of MGM S.r.l.?

In the future, it is planned to include the Quality module for Metronomo.Net, while at the company level the next objective is to increase the fleet with the arrival of new 4.0 adjustments, given also the current high workload.