Specialists in mechanical micro processing

https://www.utilita.it/Needs

Schedule orders to accurately communicate delivery dates to customers

Know monthly schedules in advance

Manage the entire production and countless orders on time

Implementation

The integration of the software began with the production scheduling module, continued with the implementation of the quality module, the quotations module; finally, with the connection of the machines and the implementation of the real MES. In this way, the department operators have had no problems during the transition to the new management methodology.

Metronomo.Net was crucial for ease of use and immediacy, especially when it comes to production planning. Customisations were then developed to adapt the software to the needs: the after-sales service is considered fundamental by the company and MecMatica has managed to support it through assistance.

Results

Immediacy with which we have all the necessary information

Traceability of information processes

Collection of history in a uniform manner and accessible to all employees

Centrality in all aspects of the business: production, sales, purchasing, quality and stock

Correct economic valuations

Control of material and external processing

Marking of machine stops

Interview

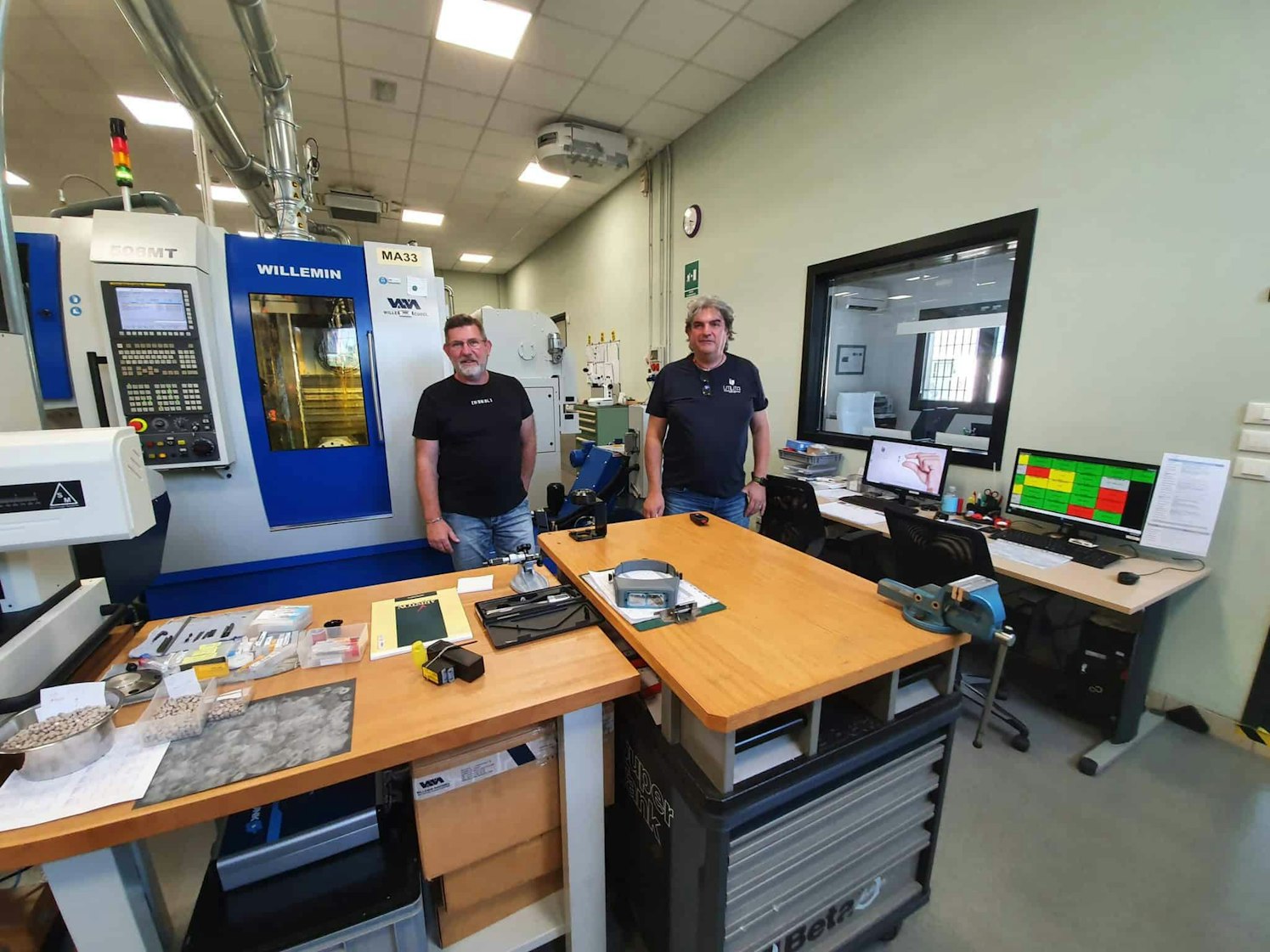

What kind of company is UTILITÀ and in which sector do you operate?

Our company was founded as a specialized contractor in the construction of micro-components for goldsmithing and watchmaking, working special metals such as gold, platinum, palladium and titanium. Currently the core business of our company is the medical implantology sector and since 2004 we have entered the aerospace sector, with regard to precision micromechanics.

In the aeronautics sector, we were able to approach thanks to the purchase of the first multitasking bar machining center.

What are your strengths?

We were among the first in Italy to work watch screws in precious materials with machine tools and initially, to buy the relevant tools, you had to go to Switzerland, home of the manufacture of watches par excellence.

Later we were able to focus a lot on precision and quality and this differentiates us from the classic "turning". Gradually moving to ever larger diameters, given the new sectors we have turned to over time, we have always managed to maintain a "precision of watchmakers.

What was the need to choose a new manager?

The initial reason was the need to schedule the various orders in order to be able to communicate precisely the delivery dates to our customers: working also with annual forecasts, we need to know in advance the monthly schedules.

The number of orders, in the order of thousands per year, made it necessary to use a computer tool that would allow us to manage in a timely manner the entire production.

What kind of software selection did you make and why did you choose Metronomo.Net?

In 2012, visiting a trade fair, we met Mr. Diego Cavalleri, partner and technical manager of MecMatica S.r.l., who proposed us Metronomo.Net which immediately impressed us for its simplicity and immediacy, especially with regard to the production planning.

We found that the software was born in our sector and that it was hyper-specialized in the world of repair shops. The graphical interface of Metronomo.Net, despite being the first time we were viewing it, allowed us to understand immediately the logic of the scheduling module, also thanks to simple color indicators, such as "Green" you are punctual and "Red" you are late.

How was the introduction and implementation of Metronomo.Net in the Company?

Initially with the production scheduling module and gradually implementing with the quality module, the quotations module, finally with the connection of the machines and the implementation of the real MES. In this way our department operators have had no problems during the transition to the new management methodology.

The technical and sales team of MecMatica has allowed us to develop customisations to adapt the software to our needs: we consider the after-sales service fundamental and with MecMatica we have always received assistance and support.

Metronomo.Net has been operating in the company for several years, what benefits have been brought?

Certainly the immediacy with which we have all the information we need, the traceability of all information processes and the ability to have all the history of the company in a uniform manner and accessible to all our employees. Metronomo.Net is central to all aspects of our business: production, sales, purchasing, quality and inventory.

The quotation module, for example, allows us to make correct economic assessments by keeping everything under control, from material to external work. The "Alert" function is also very useful for us in various aspects of production and quality. The operator declares the reasons of machine stop, also for tool change, and at any time we have the possibility to generate Gantt charts related to the production of each individual article.

The added value brought by the introduction of Metronomo.Net has also been recognized by our main customers and quality certification bodies and is important for us as our company is certified since May 2010 UNI EN ISO 9001, from May 2019 UNI EN 9100 by the body DNV-GL, and from November 2020 UNI CEI EN ISO 13485:2016 by the body ICIM.

How have you and are you facing the current global situation caused by the pandemic?

During the emergency due to the pandemic, the aerospace sector was affected and this had a great impact on our production, pushing us towards other types of work and market.

After the first lockdown, the situation has improved: many requests have arrived and the number of quotations has increased. In this historical period, the shortage of raw materials is also problematic and thanks to the MRP of Metronomo.Net it has been possible to better manage requests and supplies.

Strategies and programmes for the future of Utilità S.r.l.?

This year we intend to renew part of the fleet that will surely be interconnected to Metronomo.Net, also we plan to invest in advanced quality management instrumentation with automatic correction of the process drift in the machine, self compensating.

Currently we have connected with Metronomo.Net 100% of our machines in accordance with 4.0 parameters, including washing machine and measuring machines. One of the next steps will be to connect all quality related instrumentation as well.

We will increase the software modules related to the analysis of results, visual analytics of data, implement the Prodisplay module and reason in investments related to the visual factory, continuing profitably our collaboration with MecMatica S.r.l.